Got a napkin sketch, but need some help working out the details? We’ll help you work out the function and form of your product so it performs to specification, looks the way you want, and fits your budget. We’ll brainstorm ideas, draft design concepts, and iterate with you so your product evolves the way you want.

Prototyping, Ideation, and Testing

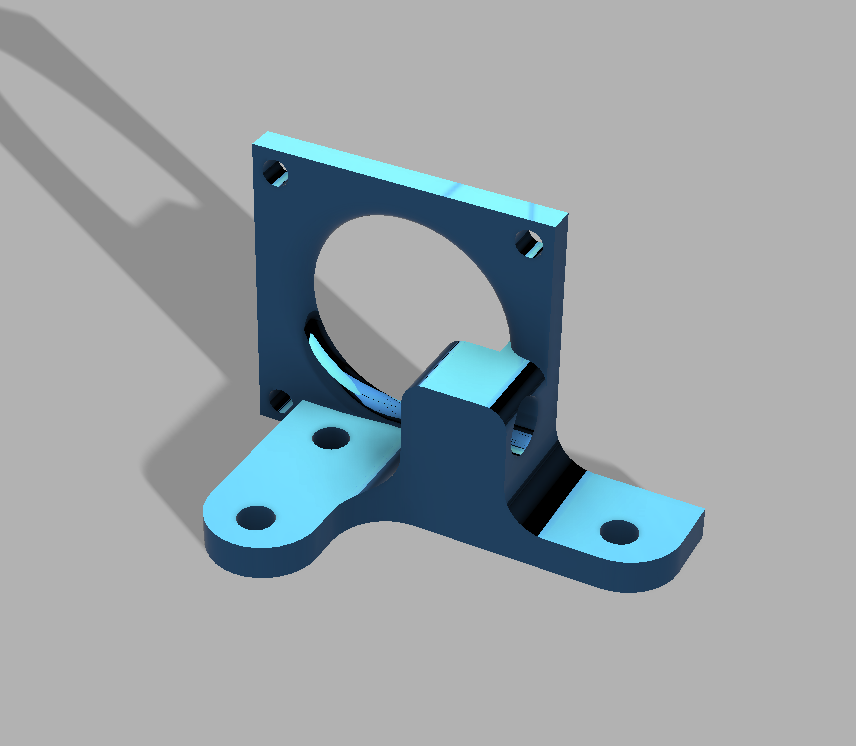

CAD Modeling And Simulation

With CAD, or Computer-Aided Design, we can turn ideas, concepts, and sketches into detailed digital 3D models. This is a critical step in hardware development because it allows end users, designers, engineers, and manufacturers understand what parts look like, how systems behave together, manufacturing and assembly, maintenance, mechanical performance, and much more. Watch your parts come to life through real-time collaboration. We apply DfMA and DfAM (where applicable) to ensure digital models can be physically reproduced.

-

We use a CAD/CAM software program called Autodesk Fusion for our 3D models, renders, and more. As part of our clear communication endeavor, we use this program so you can easily check your digital designs to make sure they meet your expectations. You can see and interact with your digital designs in real time as we update and modify them. This includes rotating the model(s) in 3D space, zooming, showing/hiding parts in assemblies, checking part dimensions, making comments, and more.

3D Printing

Cutting-edge 3D printing technologies help us rapidly produce plastic parts. We create strong parts with complex geometry in materials with a wide range of aesthetic and mechanical properties. Known as additive manufacturing, this process builds parts by extruding plastic through a nozzle in precise patterns to build a part up layer by layer.

-

Technology: FDM

Typical Applications: Small prototypes and parts with complex geometry

Printer Volume: 10 × 10 × 10” (256 × 256 × 256mm)

Resolution: 0.004" (0.1mm)

Materials: Thermoplastics (ABS, PETG, PLA, Wood-particle PLA, TPU, and more)

CNC Milling

CNC, or Computer Numerical Control, allows us to cut precise parts from stock material according to the CAD model. This technology allows us to build large parts from a wide variety of materials including plastic sheets, wood, and some metals. Contrary to the ‘additive’ nature of 3D printing, milling is ‘subtractive’, in that material is essentially removed from a larger piece in very precise ways.

-

Technology: 3-axis Gantry

Typical Applications: Large prototypes and parts with 2D geometry

Mill Volume: 30.0 x 12.0 x 3.0" (762 x 305 x 76mm)

Resolution: 0.004" (0.1mm)

Materials: UHMW, Acrylic, Polycarbonate, plywood, soft metals, and more

Metal Fabrication

With our growing array of metalworking equipment, we can make prototypes, jigs, fixtures, and even production parts. This includes custom sheet metal trays, covers, and enclosures, large structural parts that are subjected to significant mechanical loads, and custom rotary parts.

-

Bench mill

Bench lathe

Disk and belt grinders

4’ (1.2m) 16ga box and pan brake

Shear

Band saw

Sand blaster

Electronic Systems Design

We have years of experience designing complex electronic systems and enclosures. This includes sensor enclosures for medical scanning equipment, photography equipment, and more. We can prototype low-voltage equipment using Arduino, design user interfaces, and build custom enclosures.

-

Soldering station

Crimping equipment

Protoboard and breadboards

Arduino and Raspberry Pi

Circuit analysis and diagnostic equipment

Advanced Engineering Design

Critical designs need rigorous engineering in order to make sure they perform according to specifications and endure tough environments. When you need a design backed by sound engineering, CPD has the expertise. We’ve worked with a variety of design, safety, and testing protocols from NCAP, ISO, ANSI, and ASME.

Industrial Maintenance and Continuous Improvement

We have significant experience working in research, testing, and production environments. Whether you have an isolated problem that needs a mechanical solution, or you’re looking to optimize overall processes, we’ll consult with you to quickly identify bottlenecks, reduce downtime, and maximize quality.

CPD [Green]: Circular Product Development

CPD [Green] is our research and development initiative focused on environmental sustainability from an industrial product development perspective. We'll use our expertise to make your products more sustainable, whether you are improving your current design or building from the ground-up. We function as a consultant, contractor, or anything in between.